Babyplast being a dedicated micro-injection moulding machine manufacturer has been playing important role in the supporting increasing demand for miniature products for niche market applications such as medical devices, sensor housing, microfluidic pumps and applicators and some cutting-edge solutions to small parts, R&D and product development. Babyplast is the solution to material degradation for small shot volumes. This high-quality and precision are available in Hydraulic and hybrid machines to meet your injection moulding needs.

Do you have material degradation issues for small short volumes? Do you have production space limitations for a vertical injection moulding machine? The compact design of Babyplast vertical injection moulding machine is a perfect machine for insert moulding for assembly lines and automation applications. The workstation is at desk top height with an optional configuration rotary table or V-Table to improve the cycle time.

Tensile & Impact Test Specimens For Mechanical Testing

The Babyplast unique plastificiation system process material with the unique plunger and piston system without overheating and frictional stress. The material is plasticised by direct contact with the hot metal spheres in the plastification cylinder. The material residence time is significantly reduced with interchangeable piston sizes for shot volume below 1 cm³ to 36 cm³. Special polymers could be very costly, such as polymers for medical applications. Babyplast could help to save material costs from the beginning of the research & development stage. Babyplast is commonly used for injection of specimens for tensile test and impact strength test to meet ISO and ASTM test standards.

Babyplast could process hotmelt material for over-moulding of electronic components. plugs, over-moulding of protective sleeves and over-moulding plugs.

Babyplast has many advantages over custom-made embedding machines. The benefits are: minimum material lost. fast material change.

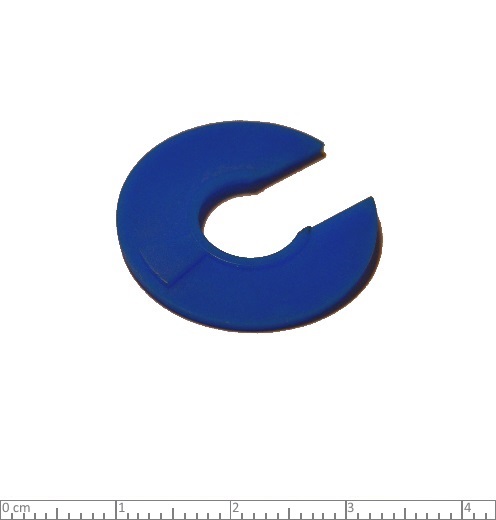

LSR injection moulding machine is available for LSR horizontal injection moulding, LSR vertical injection moulding for insert moulding application and Babyplast UAI-LSR injection unit with a stand-alone control to be integrated with any injection moulding machine to produce LSR-Thermoplastic injection moulding. Babyplast LSR machine is designed for as small as less than 1cm³ in shot volume. Commonly used for the production of seals and moulding technical parts, medical devices, automotive parts and other small parts.

The small footprint and lightweight Babyplast machine could help moulders to have significate savings in cleanroom investment and maintenance costs. E.g a 86m² clean room could house up to 36 units of Babyplast micro-injection machines set up in a double deck structure.

Babyplast is suitable to process all types of thermoplastic materials up to 420°C (PEEK). The moulded part is precise and the weight could be less than 0.1g.

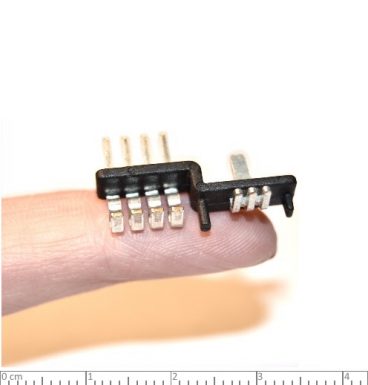

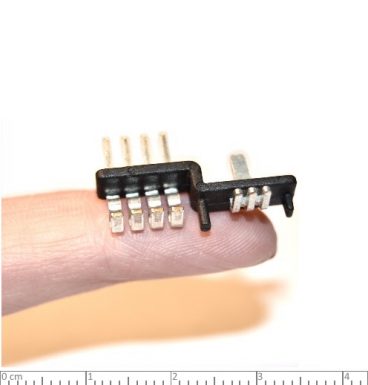

For example on the right:

Micromechanical

Material: POM

N° cavities: 4

Part Weight: 0.005 gr

Shot Weight: 0.42 gr

Babyplast UAI, is an add-on injection unit to convert any standard injection moulding machine for stack moulding.

The compact design of the Babyplast UAI injection unit is used in the production assembly line.