Babyplast

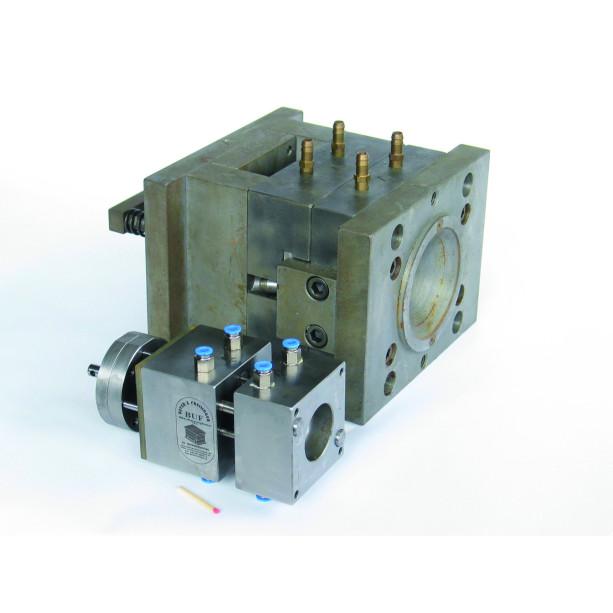

The new Babyplast 10/12-HY micro-injecting moulding machine is designed for thermoplastics processing. The combination of electric speed and hydraulic power provides precision production performance. The high...